Modern screws employ a wide variety of drive designs, each requiring a different kind of tool to drive in or extract them. The most common screw drives are the slotted and Phillips; hex, Robertson, and torx are also common in some applications. Some types of drive are intended for automatic assembly in mass-production of such items as automobiles. More exotic screw drive types may be used in situations where tampering is undesirable, such as in electronic appliances that should not be serviced by the home repair person.

Slot head

Has a single slot, and is driven by a flat-bladed screwdriver. The slotted screw is common in woodworking applications, but is not often seen in applications where a power driver would be used, due to the tendency of a power driver to slip out of the head and potentially damage the surrounding material.

Cross-head, cross-point, or cruciform

A cross-head screw drive has a cross-shaped recess. They were originally designed for use with mechanical screwing machines.[citation needed] There are five types:

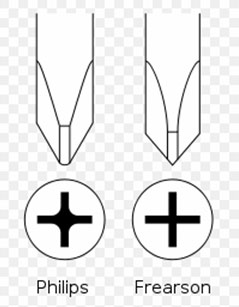

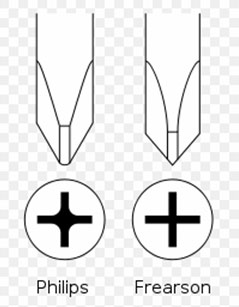

Phillips

Has slightly rounded corners in the tool recess, and was designed so the driver will slip out, or cam out, under high torque to prevent over-tightening. The Phillips Screw Company was founded in Oregon in 1933 by Henry F. Phillips, who bought the design from J. P. Thompson. Phillips was unable to manufacture the design, so he passed the patent to the American Screw Company, who was the first to manufacture it.

Reed & Prince or Frearson

Similar to a Phillips but has a more pointed 75° V shape.[39] Its advantage over the Phillips drive is that one driver or bit fits all screw sizes. It is found mainly in marine hardware and requires a special screw driver or bit to work properly. The tool recess is a perfect cross, unlike the Phillips head, which is designed to cam out. It was developed by an English inventor named Frearson in the 19th century and produced from the late 1930s to the mid-1970s by the former Reed & Prince Manufacturing Company of Worcester, Massachusetts, a company which traces its origins to Kingston, Massachusetts, in 1882, and was liquidated in 1990 with the sale of company assets. The company is now in business.

JIS

Commonly found in Japanese equipment. Looks like a Phillips screw, but is designed not to cam out and will, therefore, be damaged by a Phillips screwdriver if it is too tight. Heads are usually identifiable by a single dot to one side of the cross slot. The standard number is JIS B 1012:1985

French recess

also called BNAE NFL22-070 after its Bureau de Normalisation de l'Aéronautique et de l'Espace standard number.

Pozidriv

similar to cross-head but designed not to slip, or cam out. It does not have the rounded corners that the Phillips screw drive has. Phillips screwdrivers will usually work in Pozidriv screws, but Pozidriv screwdrivers are likely to slip or tear out the screw head when used in Phillips screws. Heads are marked with crossed, single lines at 45 degrees to the cross recess, for identification. (Note that doubled lines at 45 are a different recess: a very specialised Phillips screw.)

Supadriv

similar to Pozidriv. but with only two tickmarks instead of four. Can be used with pozidriv tools, designed to accept off-axis use of the hand tool.

Torx

a star-shaped "hexalobular" drive with six rounded points. It was designed to permit increased torque transfer from the driver to the bit compared to other drive systems. Torx is very popular in the automotive and electronics industries due to resistance to cam out and extended bit life, as well as reduced operator fatigue by minimizing the need to bear down on the drive tool to prevent cam out. Torx plus is an improved version of torx which extends tool life even further and permits greater torque transfer compared to torx. A tamper-resistant torx head has a small pin inside the recess. The tamper-resistant torx is also made in a 5 lobed variant. These "5-star" torx configurations are commonly used in correctional facilities, public facilities and government schools, but can also be found in some electronic devices.

TTAP

an improved "hexalobular" drive for without wobbling and stable stick-fit. TTAP is backward convertible with generic hexalobular (torx) drive.

|

|